Why Safe Gas Piping Installation Matters in Your Home

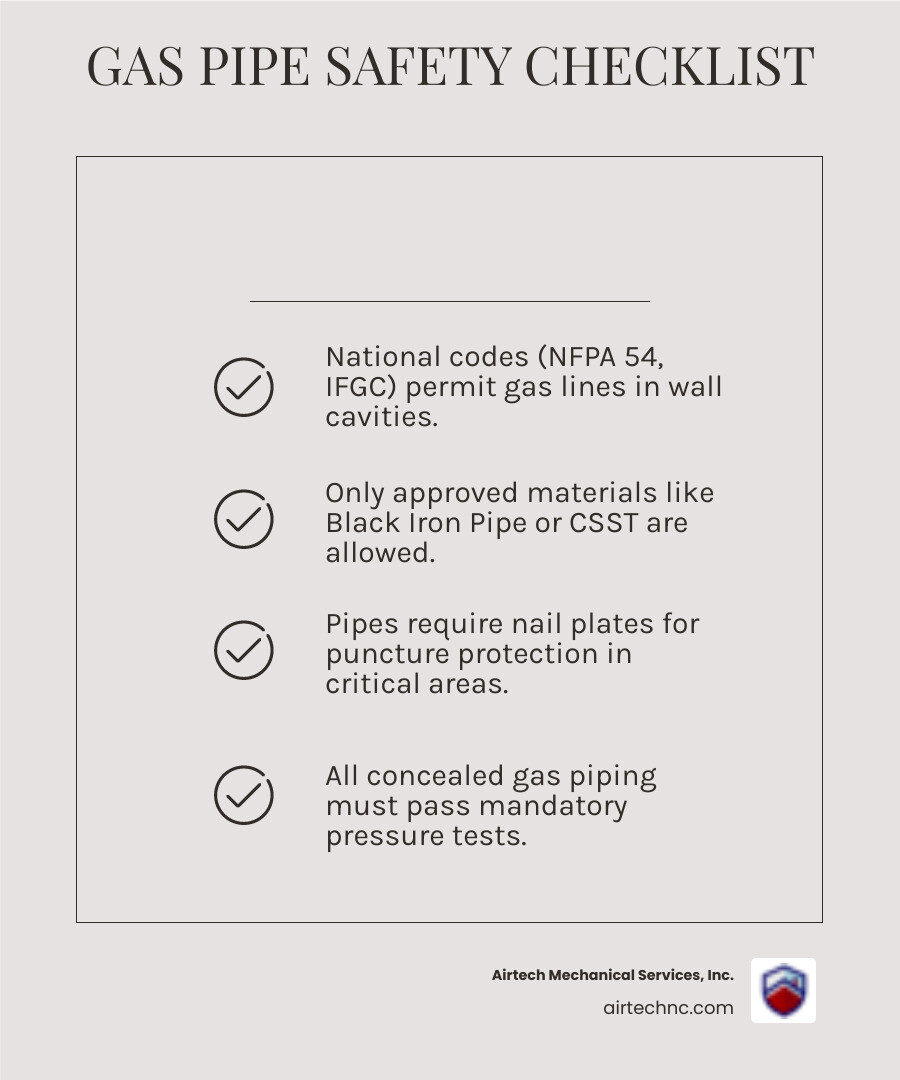

Gas pipe in wall cavity installations are permitted under national building codes, but they must follow strict safety requirements. Here’s what you need to know:

- National codes allow it: NFPA 54, International Fuel Gas Code, and Uniform Plumbing/Mechanical Code all permit gas lines in framed walls and concealed spaces

- Materials matter: Black iron pipe or CSST (Corrugated Stainless-Steel Tubing) are approved for wall cavities

- Protection is required: Pipes need nail plates where they pass near wall surfaces to prevent puncture damage

- Joints must be accessible: Unions and valves cannot be hidden behind drywall

- Pressure testing is mandatory: All concealed gas piping must pass pressure tests before walls are closed

Whether you’re renovating your coastal North Carolina home, adding a gas range, or installing a new water heater, understanding how gas pipes can safely run through your walls is essential. Many homeowners don’t realize that the invisible infrastructure behind their drywall must meet specific safety standards. Gas pipes hidden in wall cavities offer a clean, protected installation—but only when done correctly according to local building codes and professional standards.

The stakes are high: improper installation can lead to dangerous gas leaks that are difficult to detect and repair. That’s why building officials require accessible shut-off valves, protective sleeves at penetrations, and proper materials that resist puncture and corrosion. In coastal areas like ours, these requirements become even more critical due to humidity and environmental factors.

For expert guidance on safe gas line installation, check out our comprehensive HVAC services overview. If you’re ready to move forward with a project, our team offers professional gas piping and grill installations that meet all local codes.

Understanding the Basics: Gas Pipe in Wall Cavity

When we talk about running a gas pipe in wall cavity, we’re referring to the practice of installing gas lines inside the hollow spaces within your walls. This method is widely accepted by nationally recognized codes like the National Fuel Gas Code (NFPA 54), the International Fuel Gas Code (IFGC), and the Uniform Plumbing/Mechanical Code. These codes explicitly allow fuel gas lines to be run in framed walls and concealed above-ground building spaces, provided specific safety measures are in place.

The primary motivations for concealing gas piping are often aesthetic and protective. Let’s face it, exposed pipes aren’t always the most charming architectural feature! By placing them within wall cavities, we achieve a cleaner, more streamlined look for your home in areas like Atlantic Beach or Emerald Isle. Beyond aesthetics, concealing pipes offers significant protection from accidental damage, corrosion from external elements, and even makes them less susceptible to tampering.

However, the ultimate authority on what’s permissible in your home is your local building official. While national codes provide a framework, municipal regulations can have specific interpretations or additional requirements. We always recommend consulting with a licensed professional who is familiar with the codes in your specific coastal North Carolina community to ensure compliance and safety.

Inside vs. Outside: Which Route is Right?

Deciding whether to run gas pipes inside or outside your walls involves weighing several factors. Both approaches have their merits, and the “right” choice often depends on your specific home, aesthetic preferences, and local regulations.

| Feature | Running Gas Pipes Inside Walls | Running Gas Pipes Outside Walls |

|---|---|---|

| Aesthetic Appeal | High (concealed, clean look) | Low (exposed pipes can be unsightly) |

| Protection | High (protected from physical damage, weather, corrosion) | Low (exposed to elements, accidental damage, UV rays) |

| Installation | More complex (requires opening walls, precise routing, structural considerations) | Simpler (easier to run along exterior, less interior disruption) |

| Accessibility for Maintenance/Repairs | Lower (requires opening walls for access) | Higher (easily visible and accessible for inspections and repairs) |

| Safety Concerns | Potential for concealed leaks, puncture risks (mitigated by codes) | Potential for external damage, but leaks are more easily detected |

Running gas pipe in wall cavity offers a distinct aesthetic advantage, keeping your living spaces looking clean and uncluttered. It also provides excellent protection for the gas line from physical impacts, weather, and general wear and tear, which is especially beneficial in our coastal environment. However, installation is generally more complex, as it requires careful planning to route the pipe through framing and ensure proper protection. If a repair is ever needed, accessing the pipe means opening up a portion of the wall, which can be an inconvenience.

Conversely, running gas pipes outside the walls is typically simpler to install and offers easier accessibility for maintenance and repairs. If there’s a leak, it’s often more readily detected. The downside, of course, is the visual impact of exposed pipes and their vulnerability to external elements or accidental damage.

The decision should prioritize safety and code compliance above all else. Our team can help you assess the best route for your gas lines, ensuring both functionality and peace of mind.

Is It Permissible to Run Gas Lines in Walls?

Yes, absolutely! It is generally permissible to run gas pipe in wall cavity and other concealed spaces. This isn’t just a matter of convenience; it’s a standard practice supported by major national codes. As mentioned, the Uniform Plumbing/Mechanical Code, NFPA 54, and the International Fuel Gas Code all allow fuel gas lines in framed walls and concealed above-ground building spaces.

During the rough-in phase of a home renovation or new construction, you’ll often see gas lines routed through open wall studs. This ensures they are properly installed and inspected before the walls are closed up. The key is to ensure that all installations adhere strictly to these codes, as well as any specific municipal regulations in your town, whether that’s New Bern, Morehead City, or Surf City.

The permissibility comes with crucial caveats: proper materials must be used, connections must be made correctly, and specific protective measures must be implemented. We’ll dig deeper into these requirements in the following sections.

Approved Materials for Concealed Gas Piping

The choice of piping material is paramount when installing a gas pipe in wall cavity. Not all materials are created equal, and codes specify which types are approved for concealed applications. The goal is to ensure puncture resistance, corrosion resistance, and overall longevity, especially in a concealed environment where inspection is less frequent. Professional installation with approved materials is non-negotiable for safety.

Traditional Rigid Piping: Black Iron Pipe

Black iron pipe has long been a staple for gas distribution and remains a common choice for running gas pipe in wall cavity. It’s a robust, rigid material known for its strength and durability. When using black iron pipe, it’s crucial to understand the rules around fittings and connections within concealed spaces:

- Fittings: Tees, elbows (ells), and couplings are generally acceptable for use within wall cavities. These fittings, when properly threaded and sealed with approved pipe dope or tape, create secure connections.

- Prohibited Fittings: This is where we need to be extra careful. Unions and double-tapped fittings, like bushings, are typically not permitted inside concealed cavities. The reason is simple: unions are designed for easy disconnection, and bushings can be prone to cracking under stress, increasing the risk of leaks in inaccessible areas. While some interpretations allow unions if they are “accessible” via an access panel, the safest practice is to avoid them in concealed spaces altogether or ensure they are the specialized “Right-Left unions” which can be permissible in accessible spaces alongside a valve.

- Pressure Testing: Regardless of the fittings used, all black iron gas piping must undergo a rigorous pressure test before it can be concealed behind drywall. This test verifies the integrity of all connections and the pipe itself, ensuring there are no leaks.

While threading black iron pipe can be a bit more labor-intensive than some flexible alternatives, its reliability and long-standing approval make it a trusted option for concealed gas lines.

Flexible Piping: Corrugated Stainless-Steel Tubing (CSST)

Corrugated Stainless-Steel Tubing, or CSST, has revolutionized gas line installation with its flexibility and ease of routing.

This flexible, stainless-steel pipe is typically coated with yellow or black plastic and is widely used to supply natural gas in residential, commercial, and industrial structures. We often see it routed beneath, through, and alongside floor joists, inside interior wall cavities, and in attic spaces in homes across Hampstead and Newport.

One of the main advantages of CSST is its flexibility, which allows for fewer joints compared to rigid black iron pipe. Fewer joints mean fewer potential leak points, which is a big win for safety. However, CSST has its own set of installation requirements:

- Abrasion Protection: While the plastic coating offers some protection, CSST must be protected by nail guards (also known as striker plates) where it is near the face of framing members and could be pierced by finish nails or screws. This is a critical step to prevent accidental damage during or after construction. Additionally, sleeving is often required wherever CSST passes through framing holes, primarily for abrasion protection.

- Bonding: Older generations of CSST required specific electrical bonding, but newer generations, like Tracpipe Counterstrike, may not, simplifying installation. It’s essential to confirm the specific requirements for the CSST product being used.

- Professional Installation: CSST installation requires specific training and strict adherence to the manufacturer’s requirements. It’s not a DIY project. Fittings and tubing must generally be from the same manufacturer to ensure compatibility and safety.

CSST offers a quick and efficient way to run gas pipe in wall cavity, but its unique characteristics demand specialized knowledge and careful installation to ensure long-term safety and code compliance.

Critical Safety and Installation Practices

Safety is the cornerstone of any gas line installation, especially when dealing with a gas pipe in wall cavity. Preventing gas leaks, mitigating puncture risks, and ensuring fire safety are paramount. Adhering to professional standards isn’t just about passing inspection; it’s about protecting your home and family.

Protecting Your Gas Pipe in a Wall Cavity

When a gas pipe is hidden inside a wall, it needs extra layers of protection. This is where safeguards like sleeving and nail plates come into play:

-

Nail Plates (Striker Plates): These are perhaps the most crucial protection for a gas pipe in wall cavity. Where gas pipes (especially flexible ones like CSST, but also rigid pipes) pass through studs or are positioned near the face of framing members, they must be shielded by metal nail plates. These plates prevent screws, nails, or drills from accidentally puncturing the pipe during subsequent construction or when hanging pictures.

-

Sleeving Requirements: When gas pipes pass through walls or floors, they almost always need to be sleeved. A sleeve is essentially a larger pipe or conduit that the gas line runs through. This sleeve should be corrosion-resistant, impermeable to gas, and ideally have no joints. It must be sealed at both ends to the building fabric (e.g., drywall, subfloor), and the annular space (the gap between the gas pipe and the sleeve) should be sealed at one end with a non-setting, fire-resistant compound. This helps contain any potential leaks and prevents gas from migrating into other parts of the building.

- Corrosion Protection Tape: For any exposed stainless steel (such as CSST connections), only approved self-amalgamating silicone tape should be used after successful tightness testing. Using unsuitable tapes, like grease-impregnated or electrical insulation tapes, can introduce corrosive chlorides, which could compromise the pipe over time.

These protective measures are not optional; they are mandated by code to ensure the long-term integrity and safety of your concealed gas lines.

Navigating Different Wall Types

The type of wall construction also influences how a gas pipe in wall cavity can be installed. Whether it’s a load-bearing wall or a non-load-bearing partition, careful planning is required to maintain structural integrity.

- Load-Bearing vs. Non-Load-Bearing Walls: Load-bearing walls support the weight of the structure above them. Drilling or notching studs in these walls must be done with extreme caution and within strict code limitations to avoid compromising the structural stability of your home. Non-load-bearing walls offer more flexibility, but even here, excessive drilling or notching can weaken the wall.

- Drilling and Notching Studs: Building codes specify the maximum size and location of holes and notches that can be made in studs. Generally, holes should be drilled near the center of the stud, and notches should be kept shallow. Over-drilling or over-notching can severely weaken the framing, which is why a professional will always adhere to these guidelines.

- Masonry Walls: Running gas pipes within solid masonry walls (like brick or concrete block) typically involves creating chases or grooves in the masonry, or installing a furring strip wall to create a cavity. In these cases, the pipe must be adequately protected and sleeved where it passes through the masonry, and the chase must be properly sealed and fire-stopped.

Understanding these implications ensures that your gas line installation doesn’t inadvertently create structural problems for your home.

Potential Risks and How to Mitigate Them

Despite the best intentions, concealing gas piping introduces unique risks that must be carefully managed. The primary concerns are concealed gas leaks and damage to the pipe.

- Concealed Gas Leaks: The most significant risk of a gas pipe in wall cavity is a leak that goes undetected. Because the pipe is hidden, a small leak might not be immediately noticeable, potentially leading to a dangerous accumulation of gas. This is precisely why rigorous pressure testing before concealment is mandatory. Professional leak detection after installation is also vital.

- Puncture Damage: We’ve all seen it: someone hanging a picture, driving a nail, or drilling into a wall without knowing what’s behind it. Without proper nail plates, a gas pipe can be easily punctured, leading to an immediate and dangerous gas leak. This is why those little metal plates are such heroes!

- Mitigation Strategies:

- Pressure Testing: This is your first line of defense. All gas lines are pressure tested after installation but before the walls are closed. This test ensures that every joint and section of pipe is leak-free.

- Nail Plates and Sleeving: As discussed, these physical barriers protect the pipe from accidental damage.

- Professional Installation: This is non-negotiable. A licensed gas fitter understands the codes, the materials, and the best practices to minimize risks. They know where to run pipes, how to protect them, and what to look for during testing.

- Awareness of Leak Signs: Homeowners should always be vigilant for the signs of a gas leak: the distinctive “rotten egg” smell (added to natural gas for safety), a hissing sound near an appliance, or even dead vegetation near an outdoor gas line. If you suspect a leak, evacuate immediately and call your gas utility or 911.

By understanding these risks and implementing robust mitigation strategies, we can ensure the safety of your concealed gas lines.

Maintenance, Repairs, and Accessibility

Even with meticulous installation, long-term safety and serviceability are critical for any gas pipe in wall cavity. What happens if a repair is needed? How do we access it? These are important questions that codes address.

Accessing Your Concealed Gas Pipe in a Wall Cavity

The concept of “accessibility” is central to gas piping codes. While the pipe itself might be hidden, certain components must remain accessible:

- Accessible Unions and Valves: National codes generally state that unions and valves must be accessible. This means they cannot be permanently sealed behind drywall. Instead, they require an access panel or door that can be easily opened for inspection, maintenance, or repair. This allows a technician to turn off the gas supply or inspect a connection without tearing down your wall. While some sources might suggest unions are prohibited in concealed spaces entirely, the nuance lies in their accessibility. If a union is used, it must have an accessible opening.

- Shut-Off Valve Location: Each gas appliance (e.g., gas range, water heater, fireplace) must have an accessible shut-off valve located in the same room as the appliance. This allows you to quickly turn off the gas to a single appliance without affecting the entire house.

- Repair Challenges: If a leak develops in a section of pipe that is not at an accessible union or valve, repair can be more challenging. It will likely involve carefully opening the wall to expose the damaged section, performing the repair, and then patching the wall. This is another reason why proper installation and pressure testing are so vital – to minimize the chances of such an event.

Long-Term Care and Professional Inspection

While gas pipes are designed for longevity, vigilance and periodic professional checks are always a good idea, especially for concealed lines.

Here are some signs that might indicate a potential issue with a concealed gas line:

- Persistent “Rotten Egg” Smell: This is the most obvious sign of a gas leak. Don’t ignore it!

- Hissing Sound: A faint hissing sound coming from a wall could indicate a leak.

- Unexplained High Gas Bills: If your gas usage hasn’t changed but your bills are spiking, it could signal a leak.

- Physical Symptoms: Headaches, dizziness, nausea, or fatigue in occupants can be symptoms of carbon monoxide poisoning, which can be related to gas appliance issues or leaks. (Always ensure you have working carbon monoxide detectors!)

- Dead or Discolored Vegetation: If you have an underground gas line that runs near your house, dead patches of grass or plants could indicate a leak.

We recommend routine checks by a qualified professional, especially if you have an older home or suspect any issues. When we perform gas piping installations, we also suggest keeping “as-built” diagrams of where your gas lines are routed. This documentation can be invaluable for future maintenance, renovations, or in the unlikely event a repair is needed, making it easier to pinpoint the exact location of a gas pipe in wall cavity.

Frequently Asked Questions about Gas Pipes in Walls

We often get questions about installing gas pipe in wall cavity. Here are some of the most common ones we hear from homeowners in areas like Crystal Coast and Topsail Beach:

Are joints or fittings allowed in a concealed gas line?

Yes, some joints and fittings are allowed, but with strict conditions. Tees, elbows (ells), and couplings made of approved materials (like black iron) are generally acceptable within concealed spaces, provided they are properly installed and pressure tested.

However, unions and double-tapped fittings, such as bushings, are typically not permitted inside concealed cavities. The primary concern is that unions are designed to be taken apart, and bushings can be weaker points prone to cracking, increasing the risk of leaks in inaccessible areas. All joints and fittings, even those allowed, must be theoretically accessible for inspection and future maintenance, usually via an access panel. This ensures that if a problem arises, a technician can reach the connection without extensive demolition.

Does a gas pipe in a wall need to be in a sleeve?

It depends on the specific situation and local codes, but generally, yes, for penetrations. While a gas pipe (like black iron or CSST) running along the length of a wall cavity might not require a continuous sleeve, it must be sleeved where it passes through a wall, floor, or other building component.

This sleeving serves several critical purposes:

- Abrasion Protection: It protects the gas pipe from rubbing against the edges of framing members or other rough surfaces.

- Containment: In the event of a leak, the sleeve can help contain the gas and direct it to a safer, ventilated location, preventing it from accumulating within the building structure.

- Sealing: The sleeve should be sealed at both ends to the building fabric, and the space between the pipe and sleeve sealed at one end with a non-setting, fire-resistant compound.

Additionally, regardless of sleeving, pipes must be protected by metal nail plates wherever they are near the face of framing and at risk of being punctured by nails or screws. Always consult your local building codes and a qualified professional to confirm specific sleeving requirements in your area.

Can I run a gas line to a kitchen island?

Yes, you can often run a gas line to a kitchen island, but it involves specific requirements, especially if it’s going under a concrete slab. For gas pipe that is run indoors under a concrete slab (which is common for island installations), it typically needs to be run in a sleeve or conduit. This sleeve, often made of ABS or PVC, provides an extra layer of protection and allows for potential replacement without breaking up the entire slab.

It’s also important to note that specific restrictions might apply depending on the type of gas. For natural gas, running a line under a slab to an island is usually permissible with the proper sleeving. However, some codes may restrict or prohibit running propane lines to an island, especially if it involves going under a slab. Always check with your local building department and a licensed gas fitter for the precise regulations in your area, such as Swansboro or Morehead City.

Conclusion

Navigating the complexities of installing a gas pipe in wall cavity can seem daunting, but with the right knowledge and professional expertise, it’s a safe and effective way to power your home’s gas appliances. From the aesthetic benefits of concealed piping to the critical safety measures like nail plates and pressure testing, every step must adhere to strict national and local building codes.

Safety should always be your top priority. While the idea of a hidden gas line offers a clean look, its integrity behind your walls is paramount. Don’t compromise on quality or cut corners. For any gas piping project in your home, whether it’s for a new gas range, a water heater, or a cozy gas fireplace, always trust a licensed and experienced professional.

At Airtech Mechanical Services, Inc., we pride ourselves on over 20 years of expertise in providing reliable heating, AC repair, installation, and maintenance for residential and commercial clients across coastal North Carolina. Our team understands the unique environmental factors in areas like New Bern, Hampstead, and the Crystal Coast, and we are committed to delivering expert solutions that meet the highest safety standards.

For professional, code-compliant gas piping installation and peace of mind, reach out to us. We’re here to ensure your gas lines are installed safely and efficiently, allowing you to enjoy the comfort and convenience of your gas appliances for years to come. Explore our Expert Gas Piping Services today.